Cov txheej txheem:

- Kauj Ruam 1: Yam Koj Xav Tau

- Kauj ruam 2: Tsim thiab Luam Koj Cov Layout

- Kauj Ruam 3: Tshaj tawm PCB

- Kauj Ruam 4: Txhim Kho PCB

- Kauj ruam 5: Etching

- Kauj Ruam 6: Tinning (xaiv tau)

- Kauj ruam 7: Drilling

- Kauj Ruam 8: Tus Kws Tshaj Lij Tshaj Lij (Tom Qab Ob Peb Kauj Ruam Yog Yeem Yeem)

- Kauj Ruam 9: Qhib Laminate

- Kauj Ruam 10: Txhim Kho Lub Tshuab Qhuav

- Kauj ruam 11: Hardening Dryfilm

- Kauj Ruam 12: Txiav Koj Li PCB

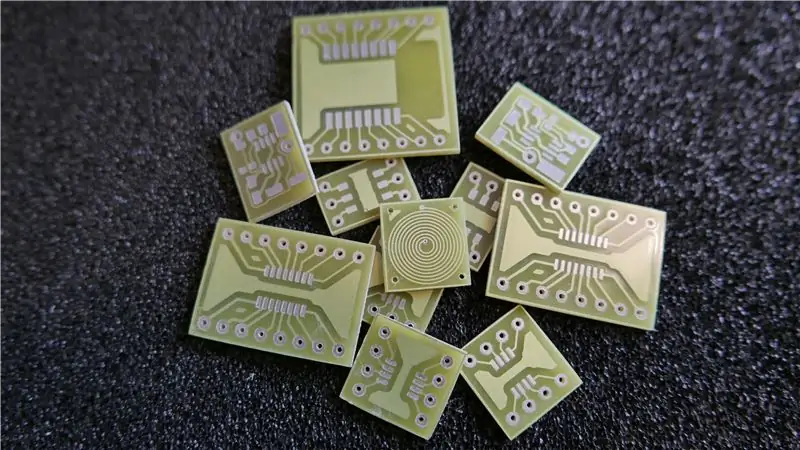

- Kauj Ruam 13: Tam sim no Koj Muaj Koj Tus Kheej Tus Kheej - Circuit -Boards

Video: PCB Etching (ua qauv): 13 Kauj Ruam (nrog Duab)

2024 Tus sau: John Day | [email protected]. Kawg hloov kho: 2024-01-30 09:27

Ua circuits yog qhov zoo tab sis ua li cas yog tias koj xav ua kom koj lub tswv yim me ntsis nyob ruaj khov? Tias yog thaum nws zoo heev uas tuaj yeem ua koj tus kheej PCBs hauv tsev.

Kuv yuav qhia koj yuav ua li cas thiaj ua rau koj tus kheej ib sab Luam Luam Circuit Board hauv tsev. Yog tias koj xav tau ib kauj ruam ntxiv koj tseem tuaj yeem kawm paub yuav ua li cas tin thiab siv cov tshuaj tiv thaiv kab mob qhuav rau nws.

Kauj Ruam 1: Yam Koj Xav Tau

Tshuaj:

- Sodiumpersulfate - Na2S2O8

- Sodium Carbonate yog. ntxuav dej qab zib - Na2CO3 (Yeem tsuas yog siv rau zaj duab xis qhuav)

- Dej distilled

- Fotopositive tus tsim tawm - NaOH

Cov ntaub ntawv:

- Cov duab coated PCB

- Tshuab luam ntawv zaj duab xis

Cov Cuab Yeej:

- Teb cuab yeej

- Jigsaw (tsuas yog tias koj npaj yuav txiav tawm qee yam ntawm koj lub pcb)

- Nibbler (tuaj yeem ua ke)

- Yas tweezers

- Ib yam dab tsi rau sanding

- Txhuam

- Raug qhov chaw nrog thav duab* (UV teeb)

- Etching chav tsev (los yog beaker thiab heatplate)

Lwm tus:

- Hnab looj tes

- Qhib lub thawv rau kev tsim kho

- Kev tiv thaiv qhov muag

- Funnel (rau sau cov kua rov qab rau hauv lawv lub raj mis)

Yeem:

- Qhuav zaj duab xis kab laug sab laminate

- Laminator

- Tshuaj kua tinning

*Kuv yuav qhia koj tom qab

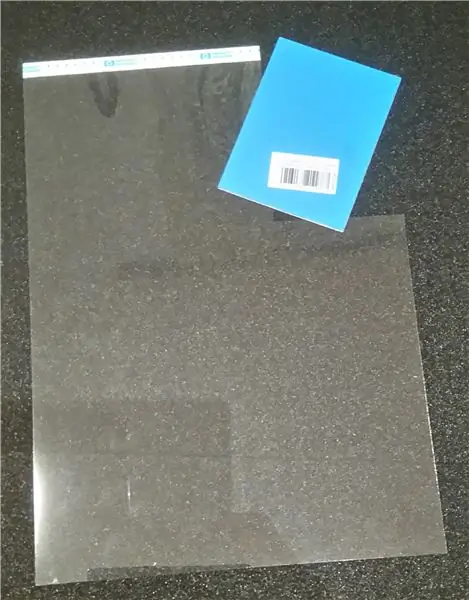

Kauj ruam 2: Tsim thiab Luam Koj Cov Layout

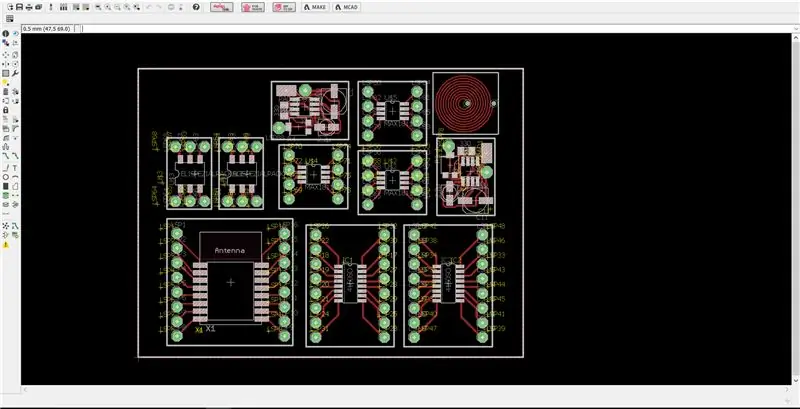

1. Siv qhov koj nyiam Cad Software (kuv yog Cadsoft eagle) los tsim PCB txheej txheem.

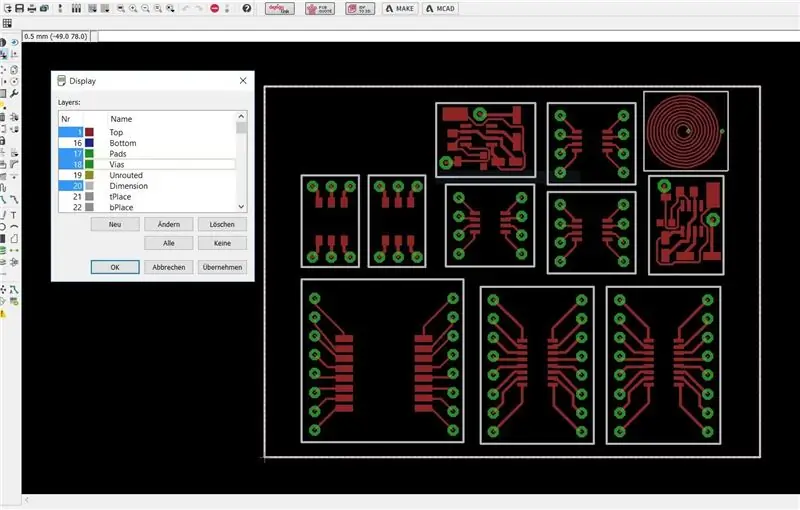

2. Qhib txheej txheej thiab tsuas yog ua kom muaj tooj liab (sab saum toj lossis hauv qab, nyob ntawm seb hom pcb uas koj npaj yuav ua), cov ntaub qhwv, Vias thiab txheej txheej.

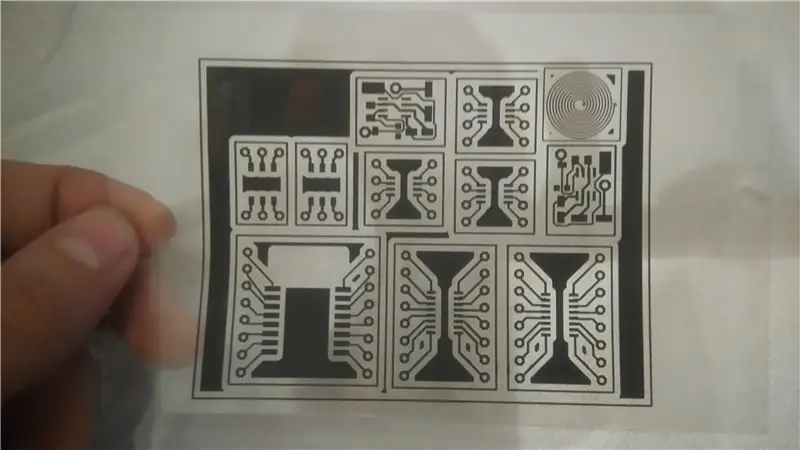

3. Muab qee cov yeeb yaj kiab tso rau hauv koj lub tshuab luam ntawv.

4. Nias lub pob luam tawm hauv koj lub software cad thiab luam tawm cov xim dub, qhov ntsuas qhov tseeb ntawm koj qhov kev teeb tsa. Nyob ntawm koj lub tshuab luam ntawv koj yuav tsum tau luam qhov txheej txheem ob zaug thiab tom qab ntawd lo ob daim duab luam tawm rau saum ib leeg kom tau txais lub teeb pom kev zoo nres.

Yog tias koj xav ntxiv cov tshuaj tiv thaiv kab mob tom qab:

1. Rov qab mus rau koj li software Cad thiab qhib cov ntawv qhia zaub mov

2. Tam sim no tsuas yog qhib txheej txheej saum toj kawg nkaus (lossis txheej txheej hauv qab-nres, dua nyob ntawm seb hom pcb koj npaj yuav ua)

3. Rov ua qhov ntsiab lus 4.

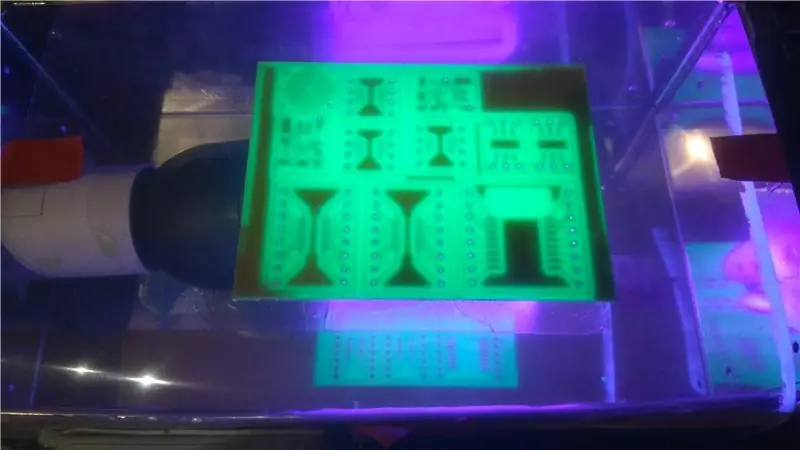

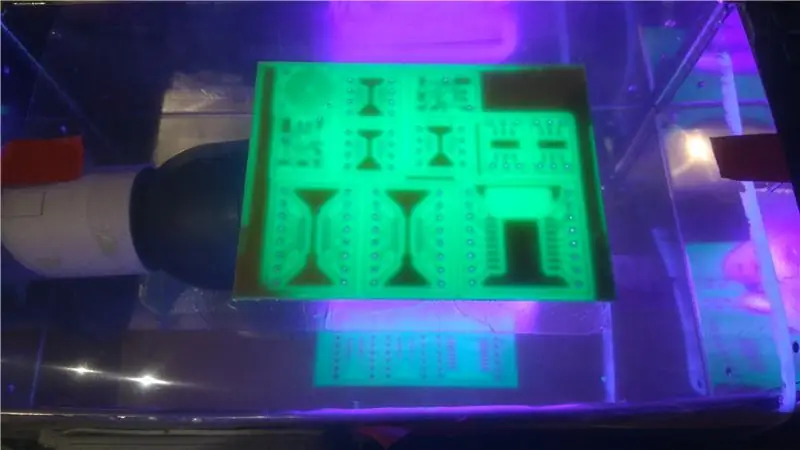

Kauj Ruam 3: Tshaj tawm PCB

1. Tev tawm txheej tiv thaiv los ntawm koj li PCB. Nco ntsoov tias koj tsis kov sab tooj liab ntawm PCB tom qab tshem cov txheej tiv thaiv vim tias yog tias koj yuav muaj teeb meem txhim kho nws

2. Teem cov zaj duab xis luam tawm thiab PCB kom tag nrho cov cim ntawm cov yeeb yaj kiab muaj tooj liab hauv qab lawv.

3. Muab cov PCB thiab cov yeeb yaj kiab uas twb muaj lawm tso rau ob daim iav iav kom cov zaj duab xis tiaj tus ntawm PCB. Siv qee cov hlau nplaum los tuav cov iav iav ua ke (zoo li pom hauv cov duab)

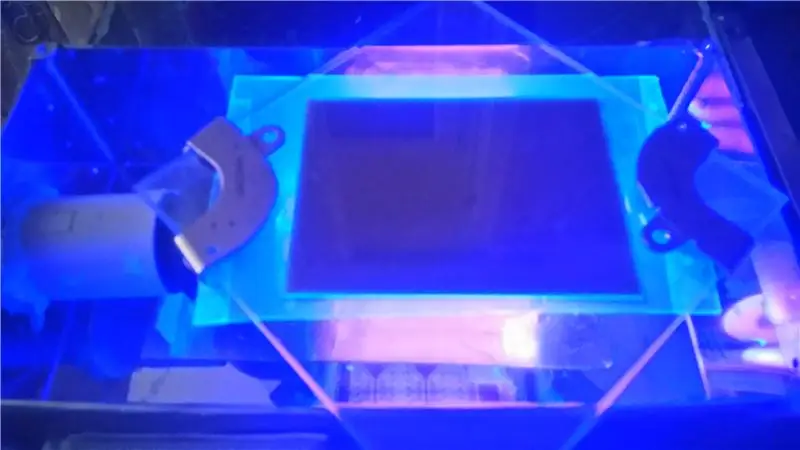

4. Tam sim no nthuav tawm PCB rau UV teeb. Kuv siv 25W tog UV teeb thiab nws siv sijhawm li 5 feeb los ua kom pom qhov tseeb

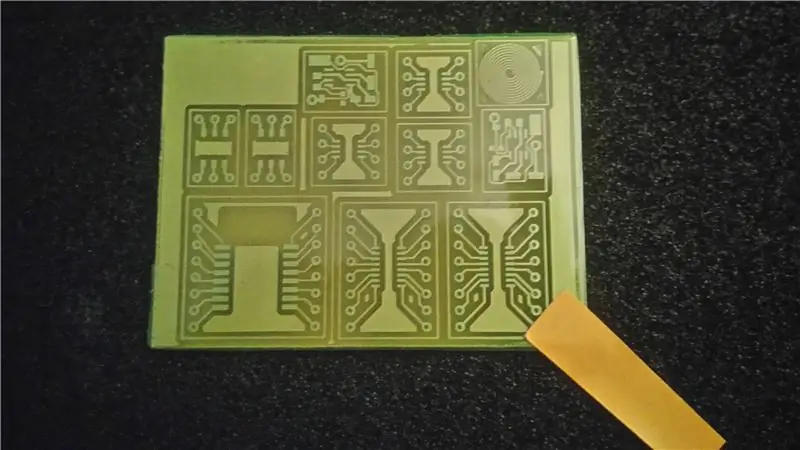

Kauj Ruam 4: Txhim Kho PCB

Tam sim no nws yog lub sijhawm los tso rau hauv koj lub hnab looj tes thiab tiv thaiv qhov muag. Tsis txhob tshem lawv tawm thaum lub sijhawm tag nrho cov txheej txheem

1. Sib tov tus tsim tawm tom qab cov lus piav qhia ntawm nws pob. Kuv yeej tsis tau sim nws kuv tus kheej tab sis 10g ntawm NaOH hauv 1 liter dej yuav tsum ua haujlwm ib yam.

2. Muab koj lub PCB tso rau hauv tus tsim kev daws teeb meem tam sim tom qab ua tiav cov txheej txheem nthuav tawm.

3. Siv koj tus txhuam los pab tus tsim tawm tshem cov photoresist.

4. Ua qhov no li ntawm 30 vib nas this kom txog thaum tsis muaj tus kws yees duab tua tawm ntxiv lawm tab sis tsis txhob coj nws tawm. Cia nws txhim kho me ntsis ntev dua li nws zoo li xav tau. Txoj kev ntawd koj tuaj yeem paub tseeb tias txhua qhov tsis tsim nyog photoresist raug tshem tawm. Txwv tsis pub koj cov txiaj ntsig cuam tshuam yuav ua rau koj lub hnub puas.

5. Yaug PCB nrog cov kais dej thiab txav mus rau theem tom ntej

CEEB TOOM:

Thaum koj ua tiav kev txhim kho coj koj tus tsim tawm thiab hliv nws rau hauv koj lub dab dej. Nws yog qhov qub tib yam khoom siv rau lub tshuab ntxhua khaub ncaws

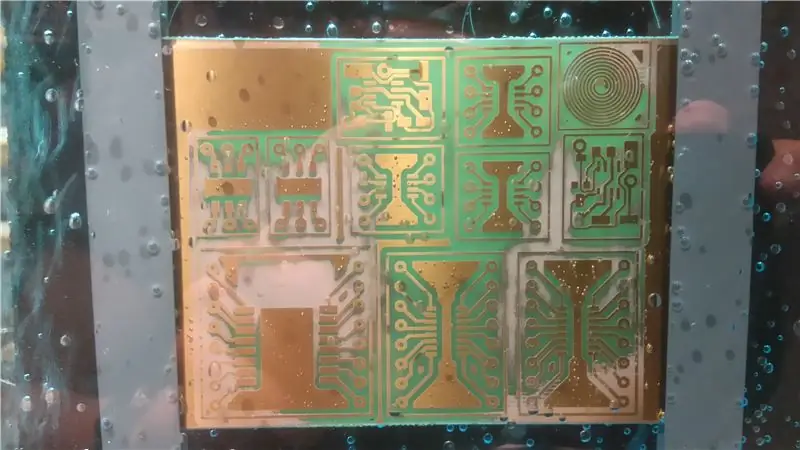

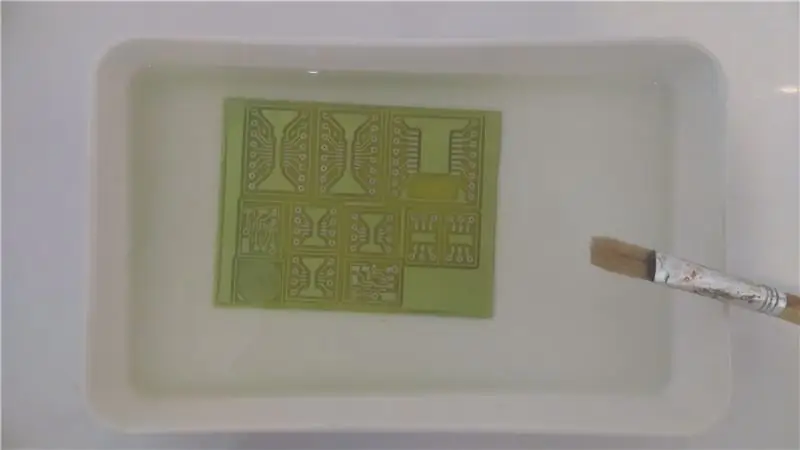

Kauj ruam 5: Etching

1. Sib tov koj tus yam ntxwv: Siv 250g ntawm sodiumpersulfate (Na2S2O8) rau ib liter dej distilled.

2. Ncuav cov etchant rau hauv koj chav tsev etching thiab sov nws mus rau 50 ° C (tsis txhob ua kom sov ntau vim tias sodiumpersulfate pib decompose ntau dua 50 ° C)

Yog tias koj tsis muaj chav tsev etching tsuas yog sau cov etchant mus rau hauv lub lauj kaub uas tiv taus cua sov thiab muab tso rau saum cov cua sov. Kuj sov nws txog li 50 ° C.

3. Sai li cov kws tshawb fawb tau mus txog nws qhov ntsuas kub kawg coj koj lub PCB, muab tso rau sab hauv thiab pib tso cua ntawm koj lub tsev tshuaj xyuas (Yog tias koj siv lub raj mis siv txoj hauv kev coj tus nplawm nplawm thiab tsuas yog sib tov nrog PCB hauv nws.)

4. Tso nws sab hauv cov tshuaj kom txog thaum tag nrho cov tooj liab tau "ploj mus"

5. Yaug PCB nrog cov kais dej.

6. Yog tias koj siv chav tsev kos cim kom ntseeg tau tias koj tshem tawm cov etchant thiab khaws nws hauv lwm lub thawv uas tsis muaj cua nkag. Txwv tsis pub koj lub tshuab cua tuaj yeem ua rau puas tsuaj.

CEEB TOOM:

Tus kws tshawb fawb yuav tig xiav thiab pib tsis muaj txiaj ntsig tom qab ob peb ntawm PCBs. Thaum koj paub tias cov txheej txheem etching pib siv sijhawm ntev dua, hloov koj tus kws tshawb fawb thiab coj tus qub mus rau koj lub chaw pov tseg tshuaj lom neeg hauv nroog Ceeb toom: "Kev siv tshuaj txhuam cov tshuaj muaj tooj liab yaj uas tsis zoo rau koj ib puag ncig"

Kauj Ruam 6: Tinning (xaiv tau)

1. Tshem tus kws yees duab ntau dhau los ntawm kev ntxuav PCB nrog acetone

2. Nqa koj cov kua tinning thiab sau nws mus rau hauv lub thawv qhib.

3. Muab koj lub PCB tso rau hauv thiab tawm hauv qhov ntawd li ntawm 5 - 10 feeb

4. Nqa PCB tawm ntawm cov tshuaj thiab yaug nws nrog cov kais dej

5. Ncuav cov kua tinning rov qab rau hauv lub raj mis iav siv lub raj mis. Khaws nws rau hauv qhov chaw uas tsis muaj tsiaj lossis menyuam tuaj yeem ncav tau.

CEEB TOOM:

Cov kua tinning tuaj yeem rov siv tau, tab sis tom qab qee lub sijhawm kev ua haujlwm yuav qis dua. Yog tias qhov no yog coj nws mus rau koj lub chaw pov tseg tshuaj lom neeg hauv ib cheeb tsam.

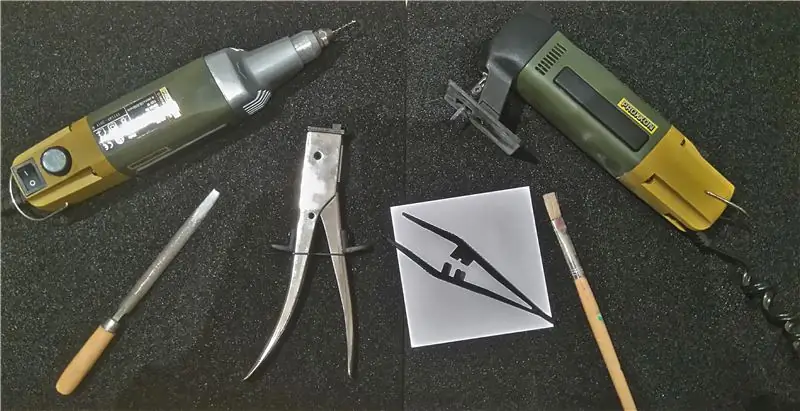

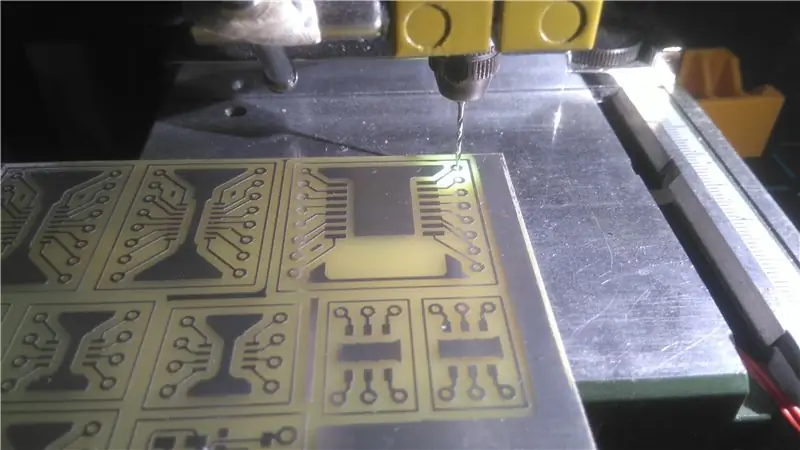

Kauj ruam 7: Drilling

1. Siv lub cuab yeej teb thiab qhov loj me me qhov me ntsis.

2. Yog tias koj muaj lub laum sawv ntsug, txhim kho koj lub cuab yeej tig rau hauv.

3. Ua kom ntseeg tau tias koj tau txais lub teeb pom kev zoo kom koj tuaj yeem pom meej tias qhov yuav tsum nyob qhov twg.

4. Laum txhua qhov uas koj xav tau

5. Ntxuav koj lub pcb.

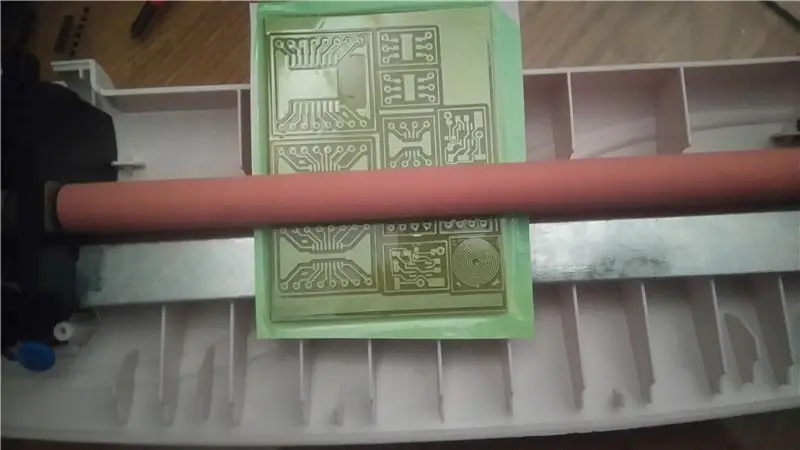

Kauj Ruam 8: Tus Kws Tshaj Lij Tshaj Lij (Tom Qab Ob Peb Kauj Ruam Yog Yeem Yeem)

Ua ntej koj pib, qhib koj lub laminator yog li koj tsis tas yuav tos nws ntawm qhov chaw 6

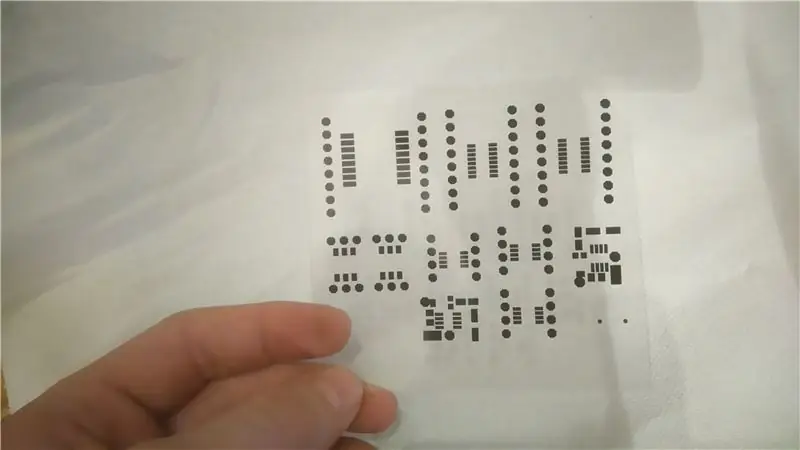

1. Tau txais qee qhov Solder tiv kom qhuav-zaj duab xis

2. Tom qab ntawd dim lub teeb thiab coj nws tawm ntawm nws lub hnab ntim khoom tsis pom kev

3. Siv ob daim kab xev muaj zog thiab lo rau saum thiab sab hauv qab ntawm ib ces kaum.

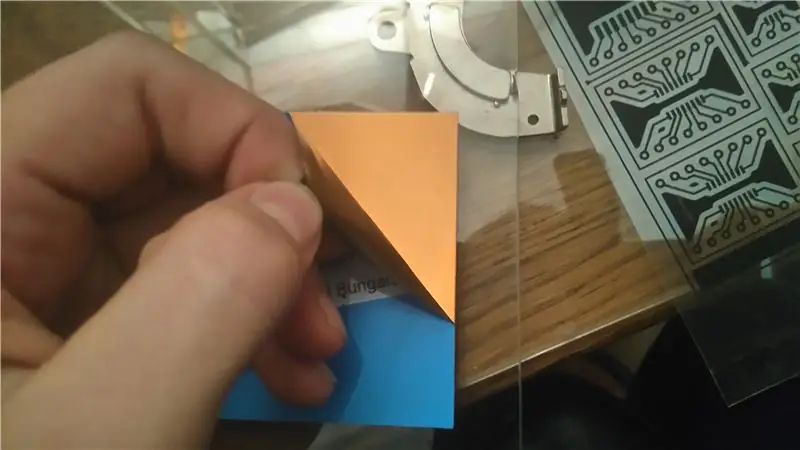

4. Tom qab ntawd rub ob daim kab xev sib nrug zoo li qhia hauv daim duab. Koj yuav xaus nrog ib pob tshab thiab ib txheej ntsuab. Muab cov pob tshab tso rau hauv lub thoob khib nyiab thiab tuav kom ntsuab.

5. Cov txheej ntsuab tau txais ob sab, ib sab yog lev thiab lwm sab yog ci. Nqa koj lub PCB thiab tso daim lev ntawm daim ntaub ziab rau nws. Xyuas kom koj tsis txhob muaj npuas nyob nruab nrab ntawm lawv.

6. Thaum koj lub laminator tau mus txog nws qhov kub kawg (uas yuav tsum yog txog 150 ° C), muab koj lub PCB tso rau hauv ib daim ntawv thiab khiav ntawm lub tshuab laminator 2 - 5 zaug. Tsuas yog xyuas kom tseeb tias tag nrho PCB tau kub.

Kauj Ruam 9: Qhib Laminate

1. Siv zaj duab xis rau daim npog ntsej muag uas koj luam tawm hauv qib 2 thiab kho nws nrog koj li PCB.

2. Rov ua dua PCB thiab zaj duab xis nruab nrab ntawm ob daim iav iav siv qee cov hlau nplaum muaj zog.

3. Tshaj tawm PCB rau UV teeb (Nws siv sijhawm li 6 feeb nrog kuv 25W UV teeb).

4. Tam sim no koj yuav tsum cia PCB so hauv qhov chaw tsaus li 1 teev.

Nco tseg: Txhua qhov chaw uas tsis raug rau lub teeb UV yuav tawm hauv txoj kev txhim kho.

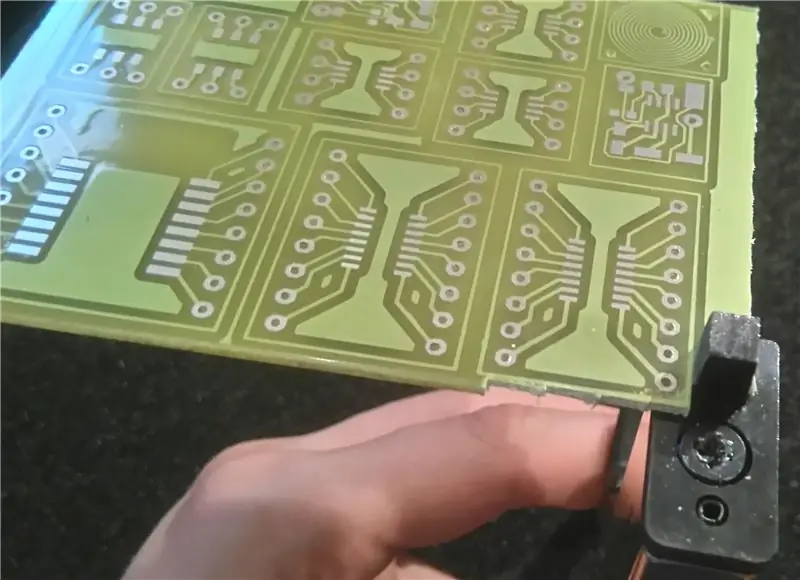

Kauj Ruam 10: Txhim Kho Lub Tshuab Qhuav

1. Sib tov tus tsim tawm los ntawm kev sib tov 10 g ntawm sodium carbonate rau hauv ib liter dej (Koj yuav tsis xav tau tag nrho litre. Kuv tsuas yog siv 100 ml ntawm nws)

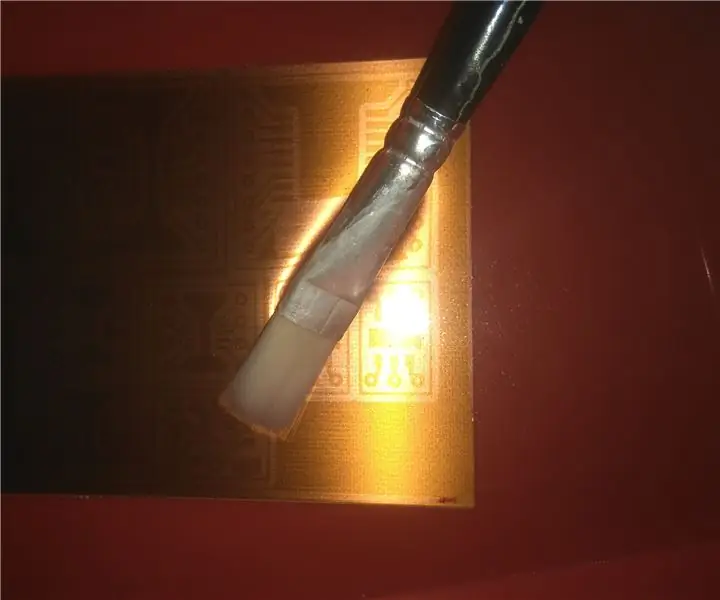

2. Tshem tawm txheej txheej tiv thaiv kawg nrog kev pab ntawm qee daim kab xev nplaum (zoo li pom hauv cov duab)

3. Muab koj lub PCB tso rau hauv tus tsim kev daws teeb meem thiab siv tus txhuam los pab tus tsim tawm tshem tawm cov kab laug sab tawm tsam los ntawm txhua daim ntaub qhwv.

4. Thaum tag nrho cov tshuaj qhuav qhuav uas tsis tsim nyog raug tshem tawm PCB los ntawm cov tshuaj thiab yaug nws nrog cov kais dej.

Kauj ruam 11: Hardening Dryfilm

1. Nqa koj lub PCB thiab tawv zaj duab xis qhuav los ntawm kev nthuav tawm rau UV lub teeb. Nrog kuv 25 W uv lub teeb nws siv sijhawm li ib teev (Kuv nthuav tawm nws rau 1/2 teev tom qab ntawd kuv tso nws txias thiab tom qab ntawd kuv nthuav tawm nws ntxiv rau 1/2 teev)

2. Koj tuaj yeem ua kom ntseeg tau tias nws tau ua tiav tawv los ntawm kev sim khawb daim duab qhuav nrog koj cov rau tes, koj yuav tsum tsis tuaj yeem khawb nws tom qab tawv tawv.

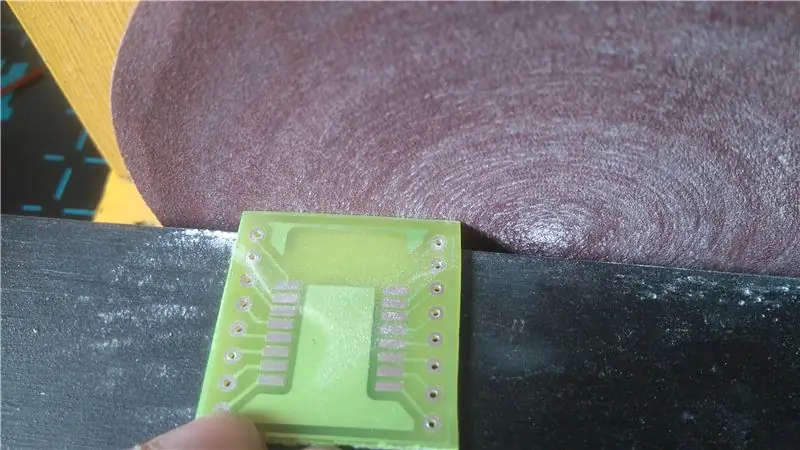

Kauj Ruam 12: Txiav Koj Li PCB

Yog tias koj tau ua nws zoo li kuv tam sim no koj yuav tsum txiav tawm koj cov laug cam me me, yog tias tsis yog koj tsuas yog xav tau txiav cov qauv ntawm ib lub rooj tsavxwm.

1. (xaiv tau) Siv cov cuab yeej nibbling los txiav tawm qhov ntxhib ntawm koj li PCB

2. Siv tus jigsaw ua raws tus qauv ntawm koj li PCB (s)

3. Siv cov xuab zeb thaiv, cov ntaub ntawv lossis cov discsander los muab koj lub rooj tsavxwm kom tiav.

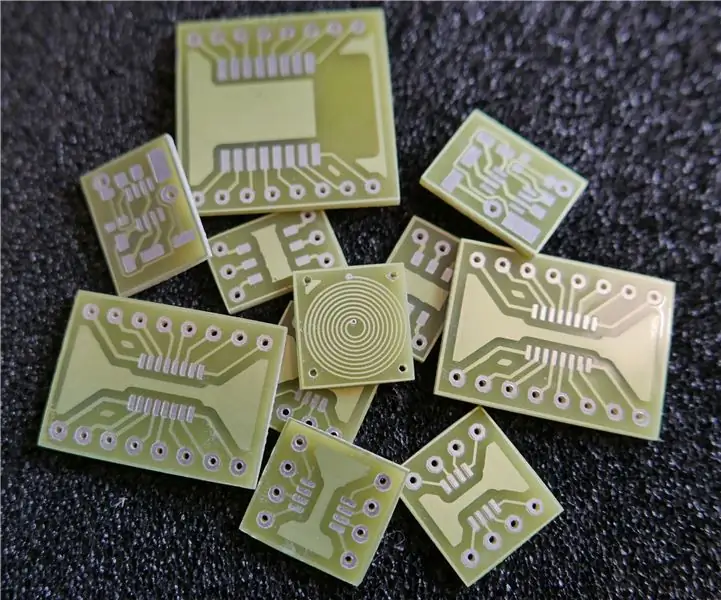

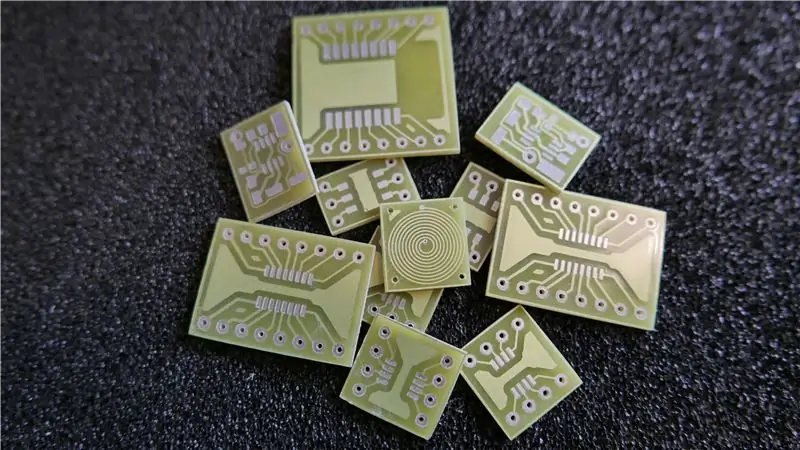

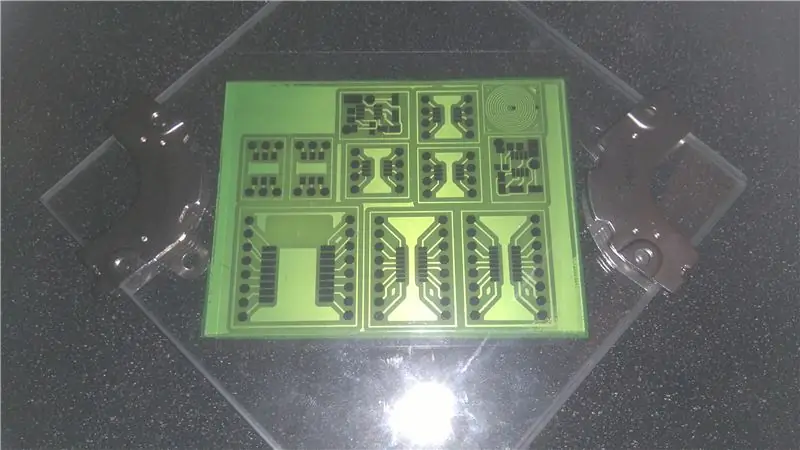

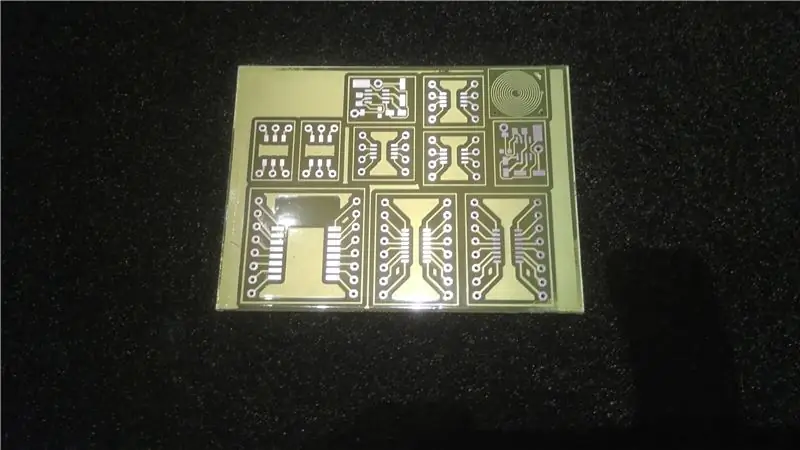

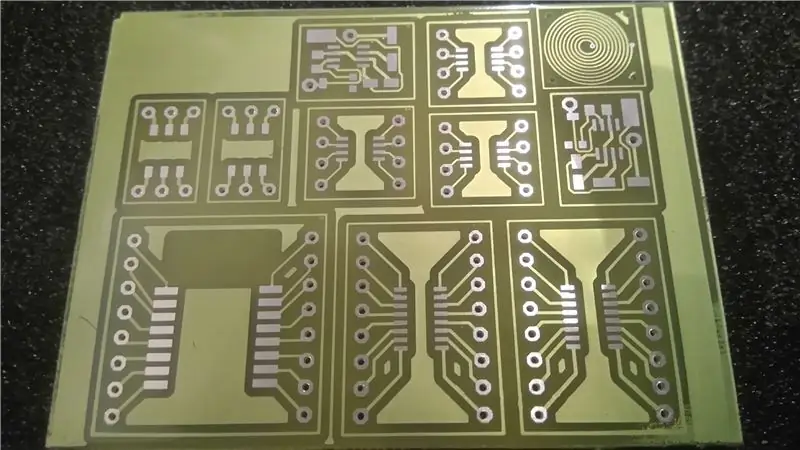

Kauj Ruam 13: Tam sim no Koj Muaj Koj Tus Kheej Tus Kheej - Circuit -Boards

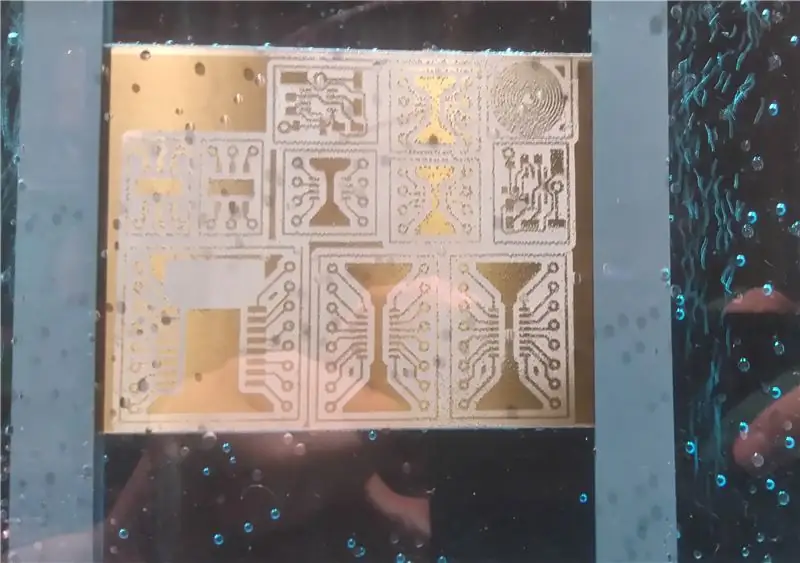

Koj ua tiav!

Qhov ntawd yooj yim npaum li cas nws yog kev cai luam tawm cov laug cam hauv tsev.

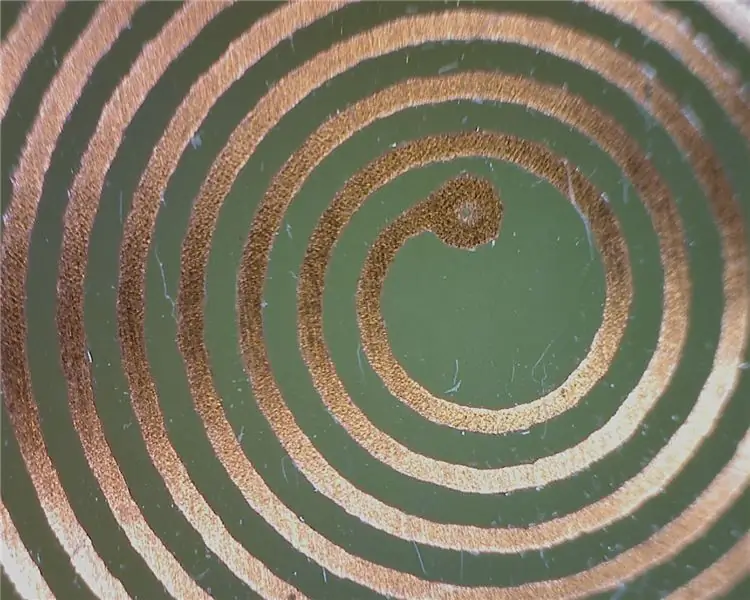

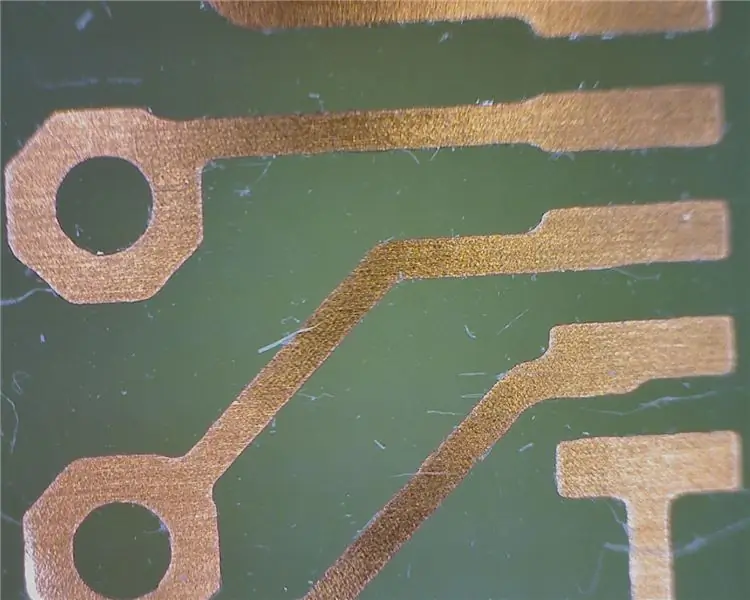

Raws li koj tuaj yeem pom hauv cov duab qhov zoo yog qhov zoo heev. Muaj qee qhov tsis zoo me me uas tshwm sim los ntawm kev daws teeb meem ntawm kuv lub tshuab luam ntawv inkjet.

Ua tsaug rau koj mloog!

Kuv vam tias koj nyiam qhov Instructables. Yog tias koj muaj lus nug dab tsi qhia lawv hauv cov lus thiab kuv yuav teb lawv sai li sai tau.

Yog tias koj ua PCB nrog kev pab ntawm cov lus qhia no tshaj tawm cov duab hauv cov lus - Kuv nyiam pom koj cov txiaj ntsig.

Pom zoo:

Qauv Cov Qauv Txheej Txheem Nrog Sab Saum: 13 Kauj Ruam (nrog Duab)

Qauv Cov Qauv Txheej Txheem Nrog Sab Saum Automated: Ua qauv qauv tsheb ciav hlau yog qhov haujlwm zoo, siv lub tshuab nws yuav ua rau nws zoo dua! Cia peb saib qee qhov zoo ntawm nws qhov kev siv tshuab: Tus nqi qis: tag nrho cov txheej txheem yog tswj los ntawm Arduino microcontroller, siv L298N mo

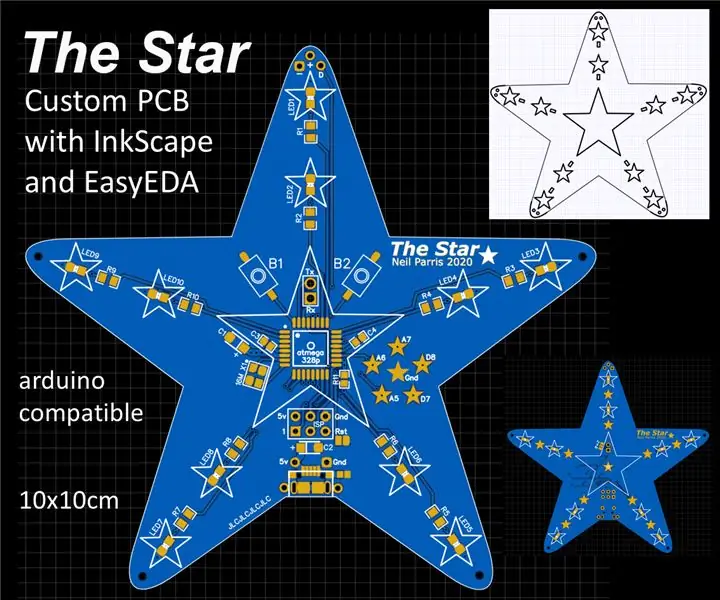

Kawm Yuav Tsim Tus Qauv Li Cas PCB Nrog EasyEDA Cov Cuab Yeej Online: 12 Kauj Ruam (nrog Duab)

Kawm Yuav Ua Li Cas Tsim Tus Qauv PCB Zoo Nrog EasyEDA Cov Cuab Yeej Online: Kuv ib txwm xav tsim tus PCB kev cai, thiab nrog cov cuab yeej online thiab pheej yig PCB tus qauv nws yeej tsis yooj yim dua tam sim no! Nws tseem tuaj yeem tau txais cov txheej txheem saum npoo sib sau ua ke pheej yig thiab yooj yim hauv ntim me me kom txuag tau qhov nyuaj

Kev Tsim Qauv Duab Duab/Duab Duab Duab: 4 Kauj Ruam

Kev Tsim Qauv Duab Duab/Duab Duab Duab: Nyob zoo txhua tus, Hauv qhov kev qhia no, Kuv yuav qhia koj cov txheej txheem ntawm yuav ua li cas thiaj tsim 3D qauv siv cov duab digital. Cov txheej txheem hu ua Photogrammetry, tseem hu ua Image-Based Modeling (IBM). Tshwj xeeb, hom txheej txheem no tau siv los rov ua dua

Qauv Cov Qauv Txheej Txheem Nrog Kev Soj Ntsuam Ntawm Sab Saum (V2.0): 13 Kauj Ruam (nrog Duab)

Qauv Cov Qauv Txheej Txheem Nrog Kev Siv Hla Dhau Sab (V2.0): Txoj haujlwm no yog hloov kho ntawm ib qho ntawm cov qauv kev tsheb ciav hlau yav dhau los kev ua haujlwm, Tus Qauv Kev Teeb Kev Teeb nrog Automated Siding. Cov ntawv no ntxiv qhov tshwj xeeb ntawm kev sib txuas thiab txiav tawm ntawm lub tsheb ciav hlau nrog cov khoom txav. Kev ua haujlwm ntawm

Tig Ib Lub Vev Xaib Yees Duab Li niaj zaus hauv Qauv Qauv luv rau ~ 40 $: 6 Cov Kauj Ruam (nrog Duab)

Tig Ib Qhov Video Projector Li niaj zaus ua qauv luv rau ~ 40 $: Raws li tus kws ua yeeb yaj kiab, Kuv nyiam ua qhov vis dis aus ncaj qha los ntawm theem. Kuv txaus siab rau txoj hauv kev no vim tias nws yooj yim dua thiab nrawm rau teeb tsa dua kom dai cov vis dis aus ntawm cov hniav nyiaj hniav kub saum toj lossis tsawg dua qhov nyuaj dua li lwm qhov kev teeb tsa. Ua tau zoo