Cov txheej txheem:

- Khoom siv

- Kauj Ruam 1: Kauj Ruam 1

- Kauj ruam 2: Kauj ruam 2

- Kauj Ruam 3: Kauj Ruam 3

- Kauj Ruam 4: Kauj Ruam 4

- Kauj Ruam 5: Kauj Ruam 5

- Kauj Ruam 6: Kauj Ruam 6

- Kauj Ruam 7: Kauj Ruam 7

- Kauj Ruam 8: Daim duab 1

- Kauj Ruam 9: Lwm Yam Dab Tsi Kuv Yuav Tsum Paub?

- Kauj Ruam 10: Daim duab 2

- Kauj Ruam 11: Cov neeg ua tim khawv

Video: DIY Tsawg-nqi UV Dej Nyab Lub Teeb rau Adhesive-free Bonding ntawm PMMA Microfluidic Chips: 11 Cov Kauj Ruam

2024 Tus sau: John Day | [email protected]. Kawg hloov kho: 2024-01-30 09:26

Microfluidic cov cuab yeej tsim nyob rau hauv cov thermoplastics tau nce siv vim muaj kev nruj, pob tshab, txo cov pa permeability, biocompatibility, thiab txhais tau yooj yim rau ntau txoj hauv kev xws li txhaj tshuaj molding. Cov txheej txheem sib txuas rau cov thermoplastics feem ntau cuam tshuam nrog kev ua kom sov siab dua li cov polymer Tg (iav hloov pauv kub) lossis siv cov kuab tshuaj uas tuaj yeem ua rau cov channel hloov pauv lossis ua rau cov tshuaj tsis xav tau los ntawm cov substrate. UV pab cov txheej txheem sib txuas tsim cov txiaj ntsig huv, tsis xav tau cov kuab tshuaj thiab tsis muaj kev hloov pauv ntawm microstructures [1]. Txawm li cas los xij, kev lag luam UV cov khoom siv hluav taws xob yog kim heev (> 2000 USD). Los ntawm kev ua raws cov lus qhia no, koj tuaj yeem tsim kho DIY tus nqi qis uas ua tau zoo ib yam li cov cuab yeej siv tshaj lij thiab ua kom rov tsim dua thiab ua kom ruaj khov ntawm PMMA microfluidic chips rau tsawg dua 100 USD.

Khoom siv

- 250 W lub teeb roj mercury (xws li Osram HQL lossis Philips HPL)

- 250 W ballast rau cov pa roj mercury

- Dej nyab lub tsev nyob nrog lub qhov (socket) sib piv rau lub teeb

- Cov xov hlau (ntu 0.5 mm2 yam tsawg kawg nkaus)

- rauj me

- Hlau hlau ntsia hlau

- Koob-qhov ntswg pliers

- Hnab ntaub tuab thiab hnab yas tuab

- Cov pa tsis muaj roj lossis cov pa roj inert

- Cov cuab yeej tiv thaiv tus kheej: hnab looj tes, daim npog plua plav, thiab tsom iav kev nyab xeeb

Kauj Ruam 1: Kauj Ruam 1

Hnav cov cuab yeej tiv thaiv tus kheej hais txhua lub sijhawm thaum tus txheej txheem no

Kauj ruam 2: Kauj ruam 2

Nrog kev saib xyuas, muab lub teeb mercury vapor tso rau hauv lub hnab yas thiab tom qab ntawd sab hauv lub hnab ntaub kom tsis txhob iav khib nyiab thiab cov hmoov fluorescent kom kis tau

Kauj Ruam 3: Kauj Ruam 3

Sab nraum zoov (lossis hauv qhov chaw muaj cua nkag tau zoo), siv rauj thiab ntsia hlau txhawm rau txhawm rau txhawm rau lub teeb lub iav sab nrauv saib xyuas ntxiv kom tsis txhob rhuav lub teeb sab hauv. CEEB TOOM: fluorescent (dawb) hmoov tuaj yeem ua tshuaj lom yog li zam kev ua pa lossis kov nws

Kauj Ruam 4: Kauj Ruam 4

Nqa lub teeb (ib txwm tuav los ntawm xov) los ntawm lub hnab thiab tshem tawm cov iav ntxiv (txog rau lub teeb hlau xov) nrog kev pab los ntawm tus pliers. CEEB TOOM: Cov iav khib nyiab yuav ntse heev

Kauj Ruam 5: Kauj Ruam 5

Ntxuav lub teeb nrog cua txias thiab khaws cia kom zoo. Tsis txhob kov lub teeb nrog tes liab qab. Muab cov iav pov tseg ua raws cov cai hauv cheeb tsam.

Kauj Ruam 6: Kauj Ruam 6

Xaim lub qhov hluav taws xob rau lub ballast thiab rau lub hwj chim qaum. CEEB TOOM: Nco ntsoov tias kev thaiv kab hluav taws xob ua rau muaj kev pheej hmoo loj. Yog tias thaiv tsis raug, koj tuaj yeem ua rau poob siab lossis hluav taws xob lossis lub cuab yeej tuaj yeem ua rau hluav taws kub. Yog tias koj tsis paub meej tias koj tab tom ua dab tsi koj yuav tsum tso cai rau ib tus neeg tshaj lij hauv kev txuas hluav taws xob ua txoj haujlwm

Kauj Ruam 7: Kauj Ruam 7

Ntsia lub teeb (lub teeb mercury) mus rau lub qhov (socket) lub teeb nyob hauv tsev. CEEB TOOM: txaus ntshai UV hluav taws xob thiab ozone tau tsim los ntawm lub teeb thaum lub hau sab nrauv raug tshem tawm. Ib txwm hnav qhov muag thiab tiv thaiv daim tawv nqaij kom zoo thiab siv lub kaw lus nyob ib puag ncig qhov cua

Kauj Ruam 8: Daim duab 1

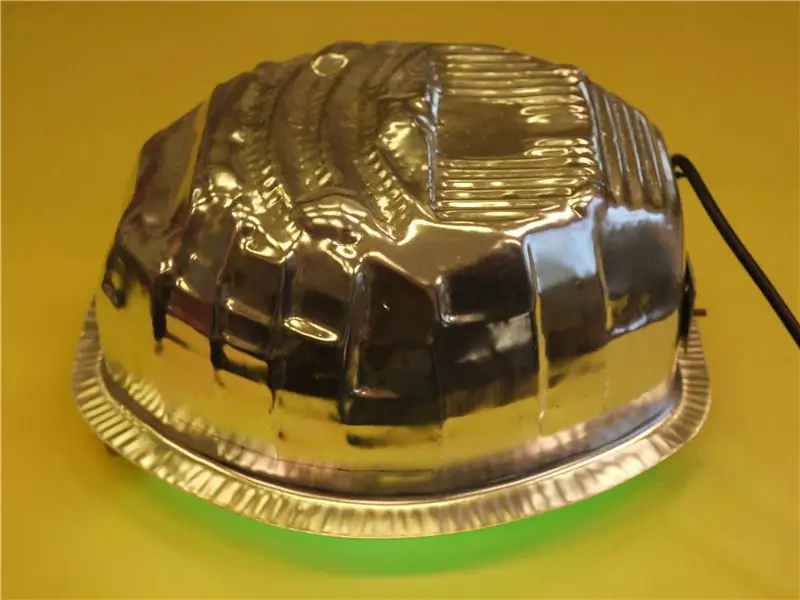

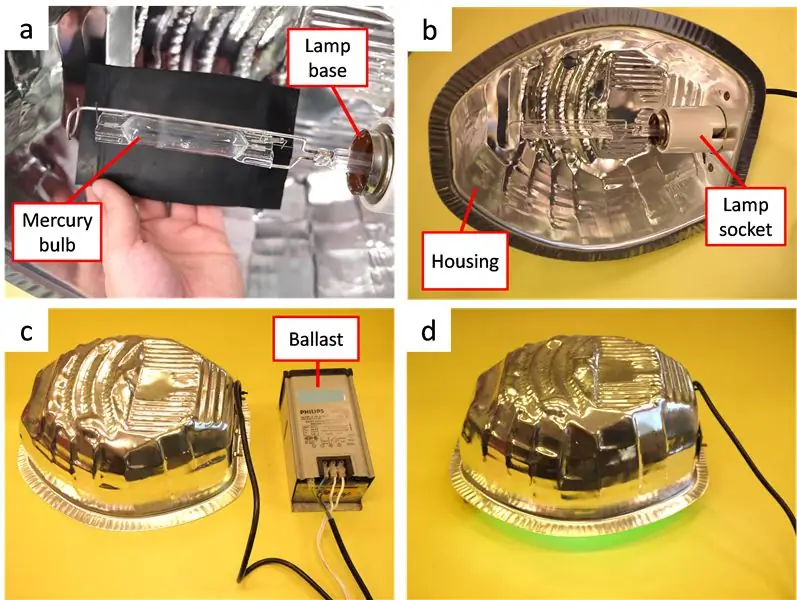

Daim duab 1. a) Cov ncauj lus kom ntxaws ntawm cov teeb meem mercury quartz, cov roj hmab dub tsuas yog nyob rau qhov kev xav pom. b) Duab duab ntawm lub tsev, teeb, thiab lub qhov (socket). c) Duab duab ntawm lub teeb dej nyab thiab ballast. d) Duab ntawm UV teeb ON

Kauj Ruam 9: Lwm Yam Dab Tsi Kuv Yuav Tsum Paub?

Lub hom phiaj ntawm qhov kev qhia no yog los qhia yuav ua li cas tsim kom muaj tus nqi qis UV dej nyab lub teeb rau kev ua photodegradation ntawm PMMA cov qauv rau kev sib txuas. Cov khoom sib txuas yuav tsum tau ua kom zoo raws li lub teeb, tsev nyob, nrug deb ntawm UV qhov chaw, hom PMMA, thiab lwm yam. Yog xav paub ntau ntxiv hais txog cov ntaub ntawv [1].

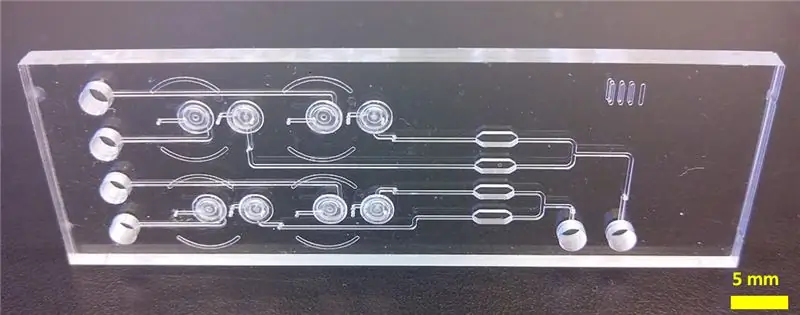

Microfluidic chips raws li qhov qhia hauv daim duab 2 tuaj yeem tau txais los ntawm kev siv lub teeb sib txuas no.

Kauj Ruam 10: Daim duab 2

Daim duab 2. Multilayer PMMA microfluidic nti sib txuas nrog cov teeb pom kev UV

Kauj Ruam 11: Cov neeg ua tim khawv

1- Truckenmüller, R., Henzi, P., Herrmann, D. li al. Microsystem Technologies (2004) 10: 372

Pom zoo:

Txhim Kho Lub Teeb Dej Nyab Teeb rau LED: 7 Kauj Ruam

Txhim Kho Lub Teeb Dej Nyab Teeb rau LED: Kuv tau teeb tsa hauv kuv lub tsev lub sam thiaj muaj 500W lub teeb dej nyab nyab rau ntau xyoo dhau los. Tab sis kuv xav tias 500W tsim nyog sim hloov nws mus rau qee yam niaj hnub thiab txuag hluav taws xob. Hauv kuv qhov kev tshawb nrhiav ib puag ncig hauv internet qee yam uas hu ua l

Dej Nco Dej Dej Lub Raj Dej: 16 Cov Kauj Ruam

Nco Ntug Dej Cov Dej Lub Raj Dej: Koj puas tau hnov qab haus koj cov dej? Kuv paub kuv ua! Tias yog vim li cas kuv thiaj los nrog lub tswv yim tsim lub raj mis dej uas ceeb toom koj kom haus koj cov dej. Tus tuav lub raj mis dej muaj qhov tshwj xeeb uas lub suab nrov yuav nrov txhua teev kom nco koj

Tsim kom muaj DIY Tus Kheej Dej Dej Nrog WiFi - Dej Tsob Ntoo Tuaj thiab Xa Kev Ceeb Toom Thaum Dej Tsawg: 19 Kauj Ruam

Ua DIY Tus Kheej Tus Kheej Dej Nrog WiFi - Dej Tsob Ntoo Tuaj thiab Xa Kev Ceeb Toom Thaum Dej Tsis Tshua: Cov ntawv qhia no qhia koj yuav tsim kho li cas Wi -nkaus txuas nrog tus kheej cog cog dej siv lub qub vaj cog, cov thoob khib nyiab, qee cov nplaum thiab tus kheej Watering Pot Subassembly Kit los ntawm Adosia

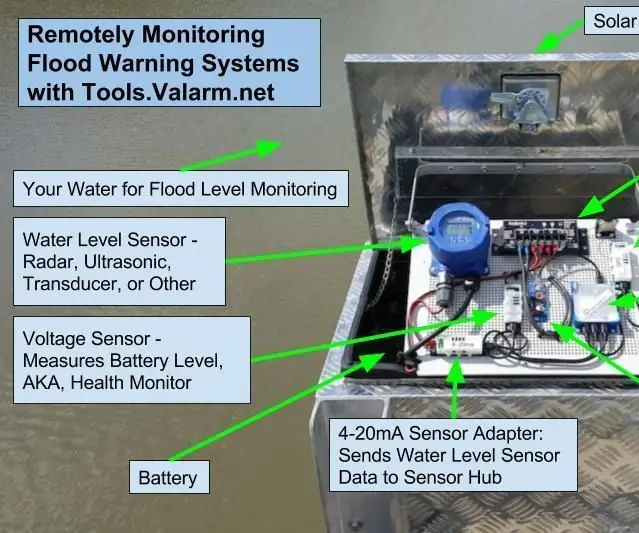

Cov Lus Ceeb Toom Txog Dej Nyab - Cov Dej Dej + IoT Sensor Saib Xyuas Phau Ntawv Qhia: 6 Cov Kauj Ruam

Cov Lus Ceeb Toom Txog Dej Nyab - Cov Dej Dej + IoT Sensor Phau Ntawv Qhia Saib Xyuas: Koj puas xav tau los saib xyuas cov qib dej? Cov Khoom Siv IoT no tau siv los ua kev ceeb toom txog dej nyab hauv Asmeskas. Txhawm rau kom koj thiab koj lub zej zog muaj kev nyab xeeb, Lub Nroog Ntsej Muag yuav tsum tau

Txaus Siab Rau Koj Tus Kheej Tsuas Yog Siv 12V-rau-AC-kab Inverter rau LED Lub Teeb Hluav Taws Xob Tsis txhob Rov Ua Rau Lawv rau 12V.: 3 Cov Kauj Ruam

Txaus Siab Rau Koj Tus Kheej Tsuas Yog Siv 12V-rau-AC-kab Inverter rau LED Lub Teeb Hluav Taws Xob Tsis txhob Rewiring Lawv rau 12V: Kuv txoj kev npaj tau yooj yim. Kuv xav txiav cov phab ntsa uas siv hluav taws xob LED teeb ua ib daim ces rov txuas nws kom khiav tawm 12 volts. Lwm txoj hauv kev yog siv lub zog hloov pauv, tab sis peb txhua tus paub tias lawv tsis muaj txiaj ntsig zoo, puas yog? Txoj cai? Los yog lawv?